3B, over 50 years

of manufacturing

experience

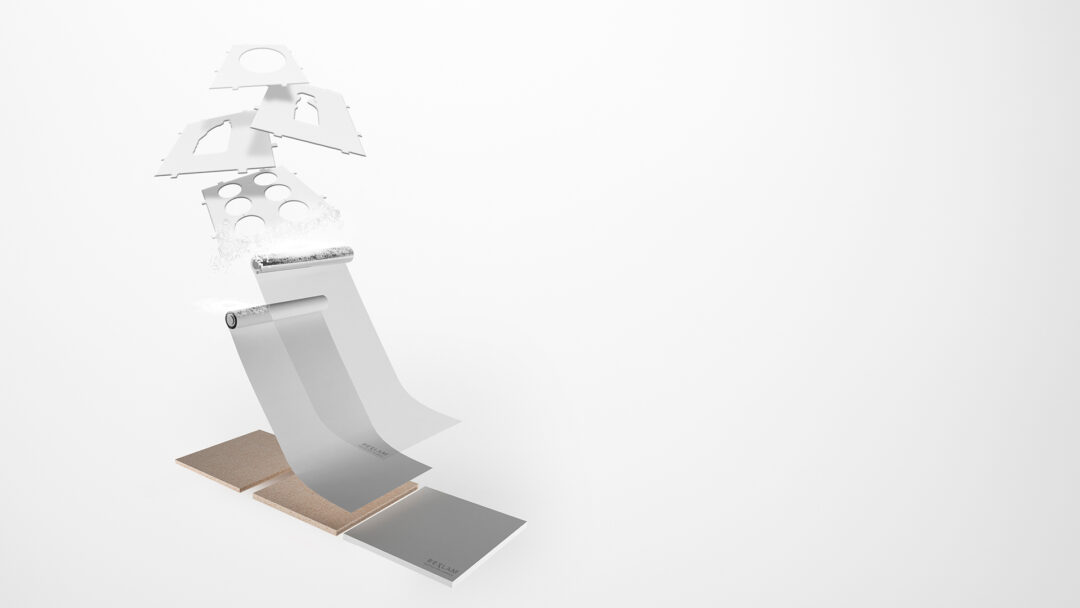

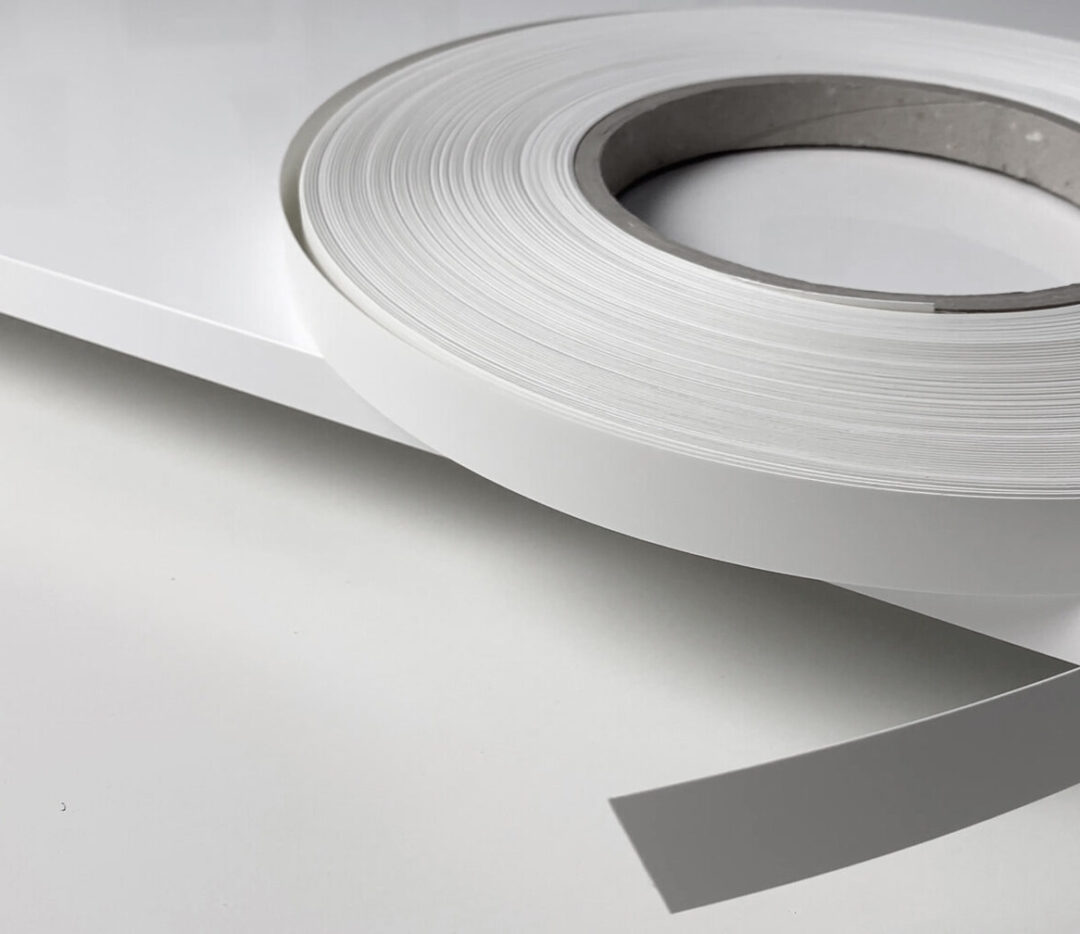

A great manufacturing capability over 50 years of experience: 3B manufacturing plant is equipped with a vast range of technologies for flexible as well as mass production of furniture and a large choice of production processes and finishes: flat lamination, wrapping, post-forming, 3D forming, edge banding, cutting, drilling, packing. High gloss surfaces, supermatt finishes, solid colors, wood grains, structured surfaces…

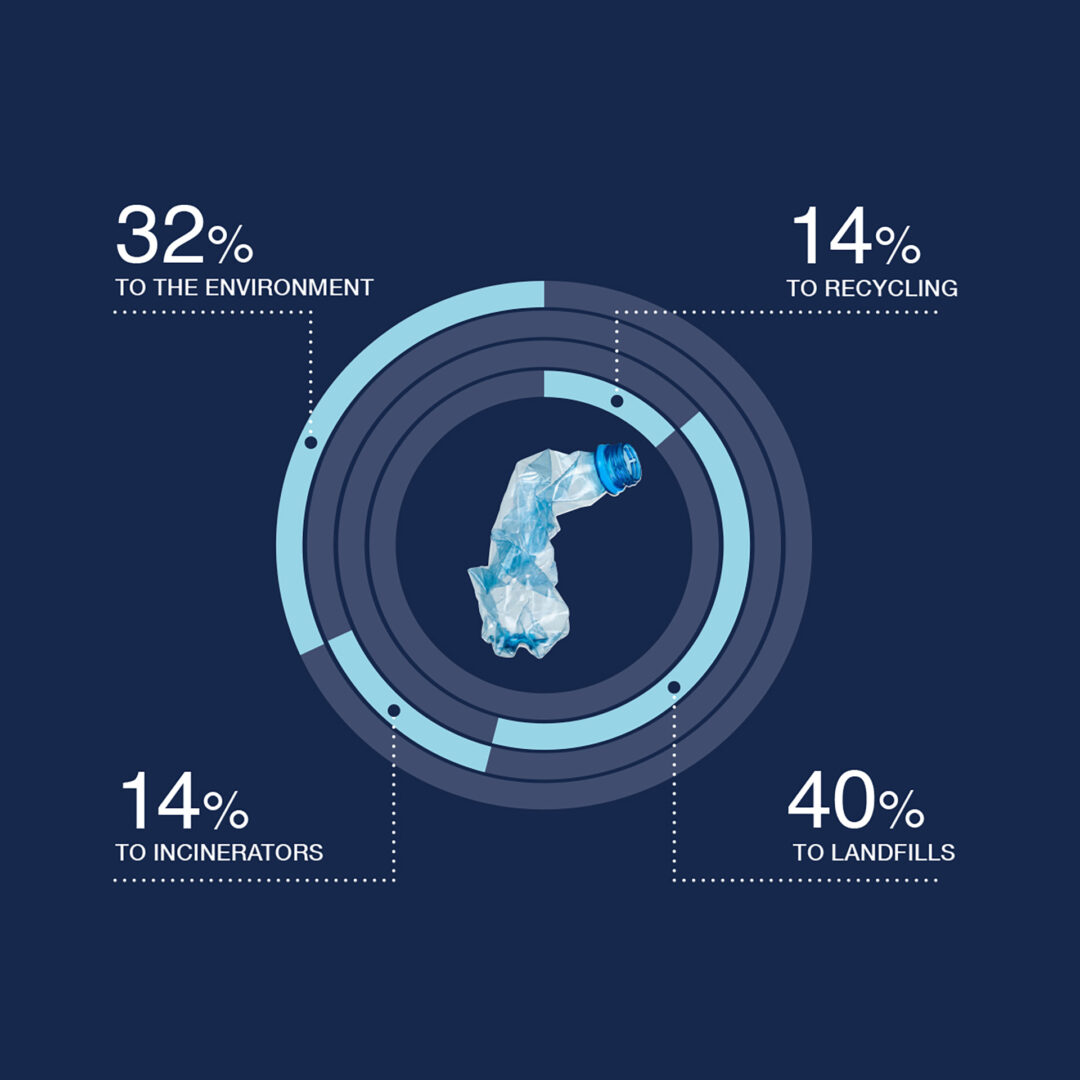

DIVENTA MEANS INNOVATIVE SUSTAINABLE MATERIALS

• Respet®, 100% recycled PET foils

• Particleboard panels from recycled wood

• Low Formaldehyde emission boards

• FSC-HEPA certifi cations

• EPA CARP P2 and FSC certifications

Diventa means flexible production system

• Low minimum order quantity on a large number of finishes and materials that are in stock

• Advanced logistic capabilities that allow to stock finished products and to ship them worldwide when required